鍛造廠

冷鍛加工廠

冷間鍛造廠

台中鍛造廠

台中冷鍛加工廠

-

公司簡介

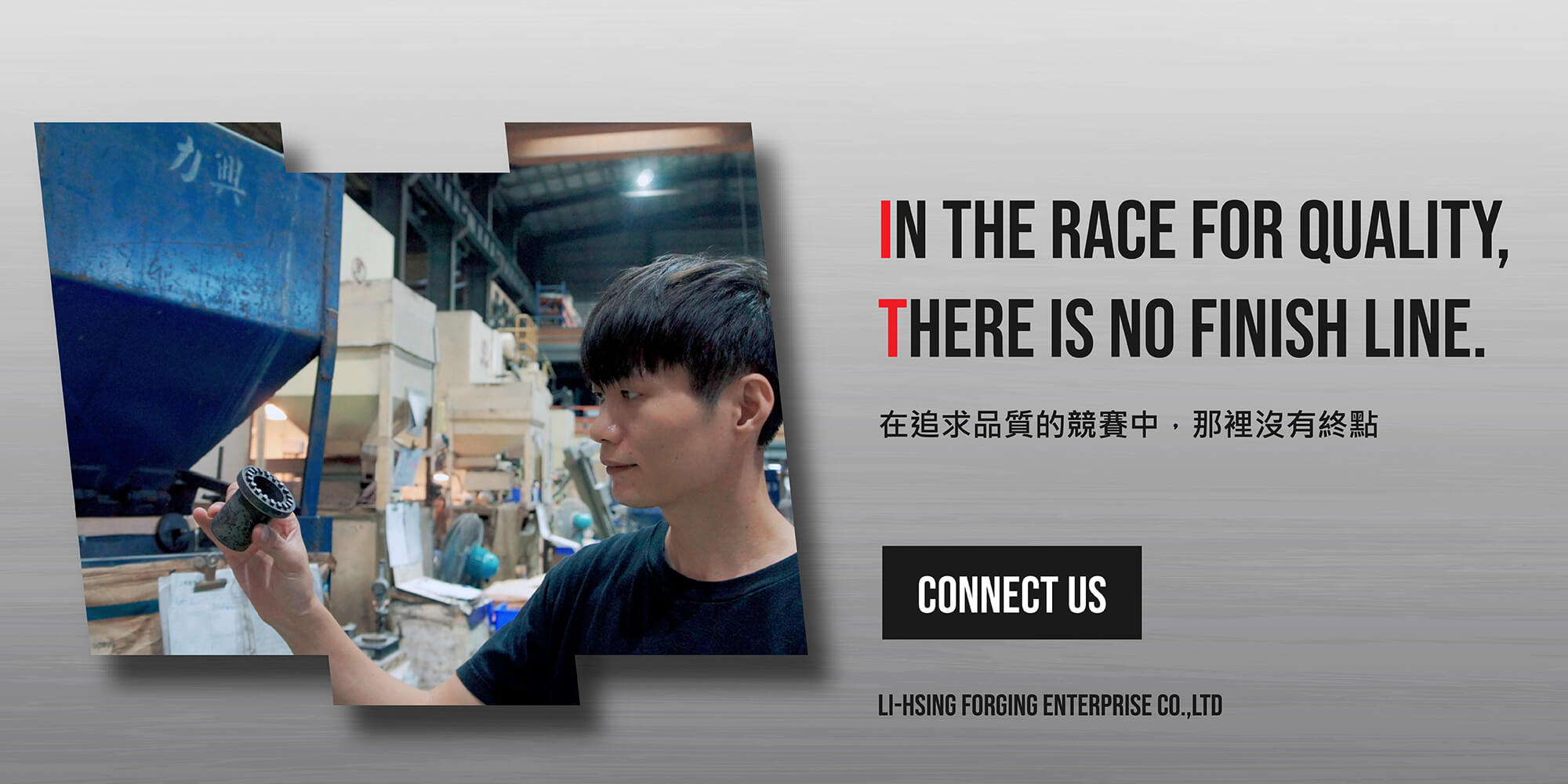

力興是一間通過ISO 9001:2015及IATF16949:2016國際認證之合格汽機車零件供應商。

由總經理江榮華先生在1984年創立,隨著時間已成功累積大量冷間鍛造之經驗及成功量產大量客製化鍛件。擁有一站式冷間鍛造及溫間鍛造設備包含鋸料機、 球化退火爐、 表面磷化處理線、鍛造機、高週波加熱爐等,都會在力興廠內完成,不需要委外加工。同時我們擁有自己設計模具與製作模具之能力,設計模具方面除了依靠過去累積之鍛造經驗,也搭配鍛造模擬軟體,來縮短新開發產品之摸索時間。

模具製作設備包含CNC車床、 線切割、 放電機,

模具設計好,可以馬上進入模具製作,來縮短新開發產品之模具製作時間。

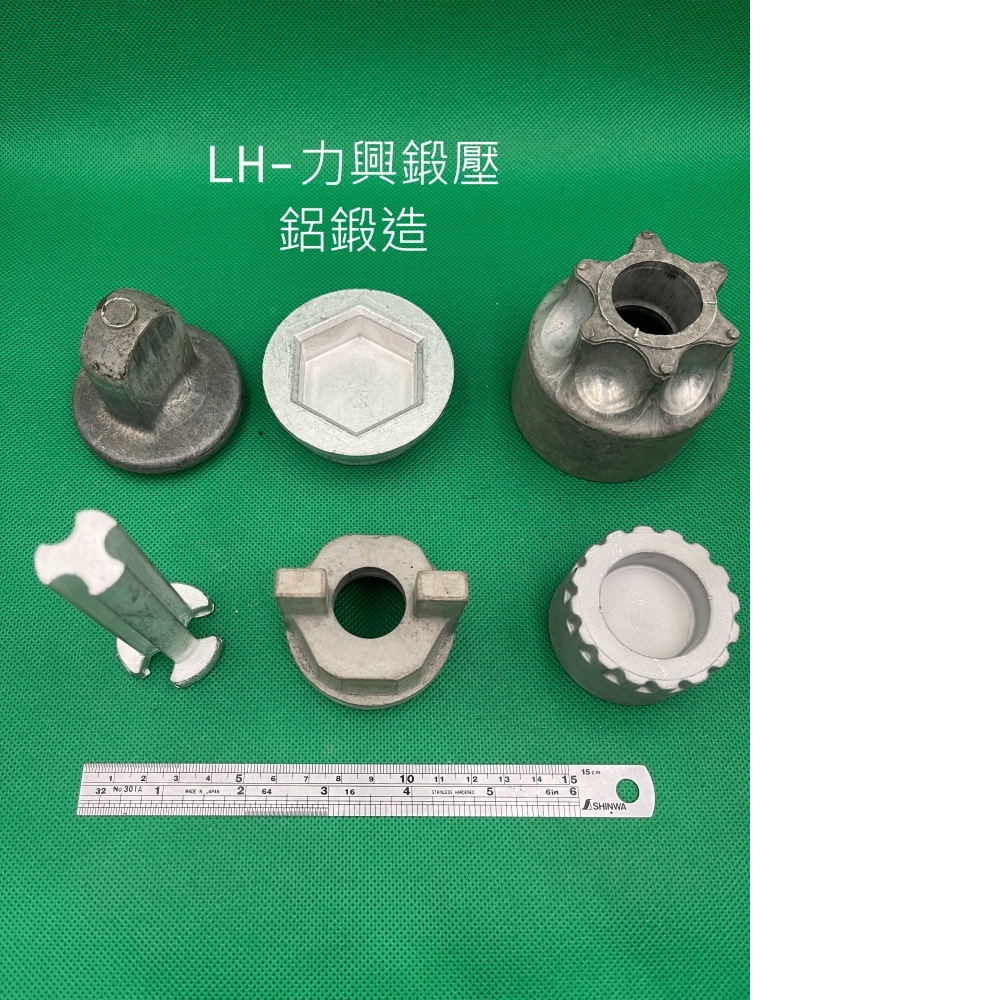

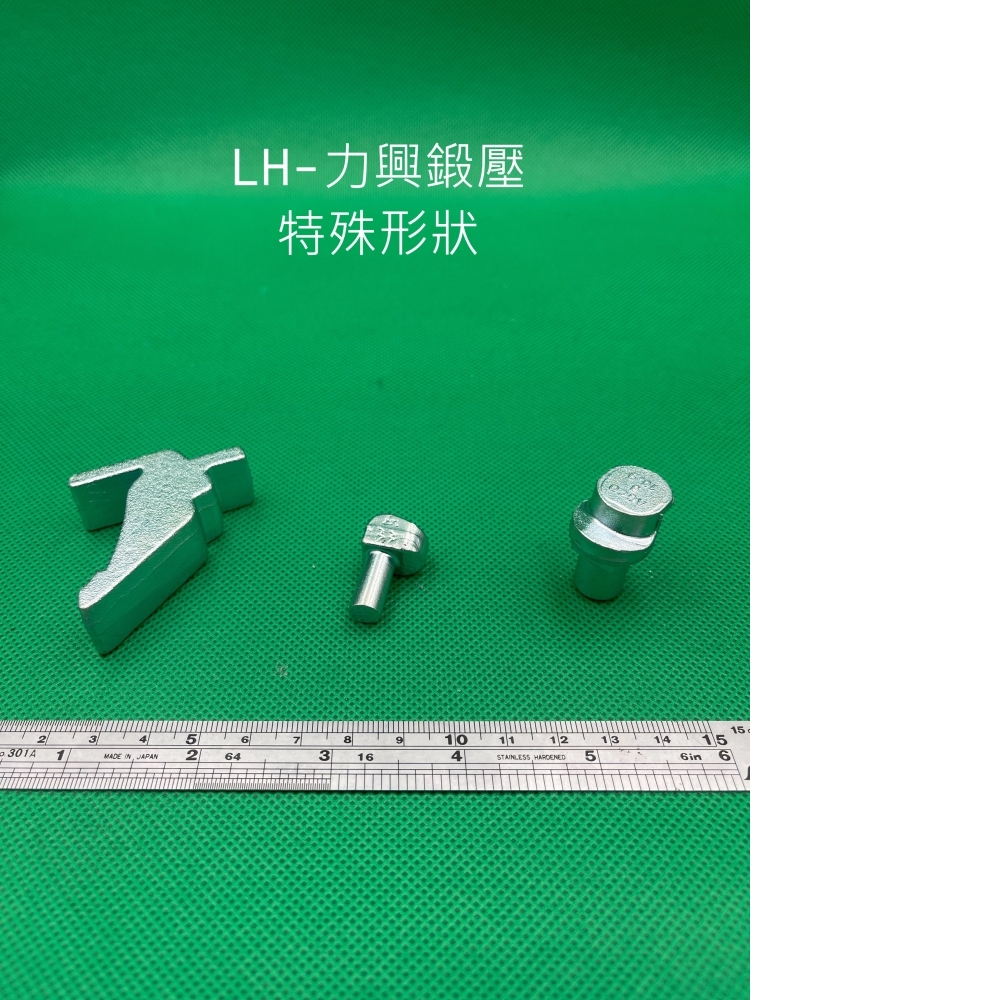

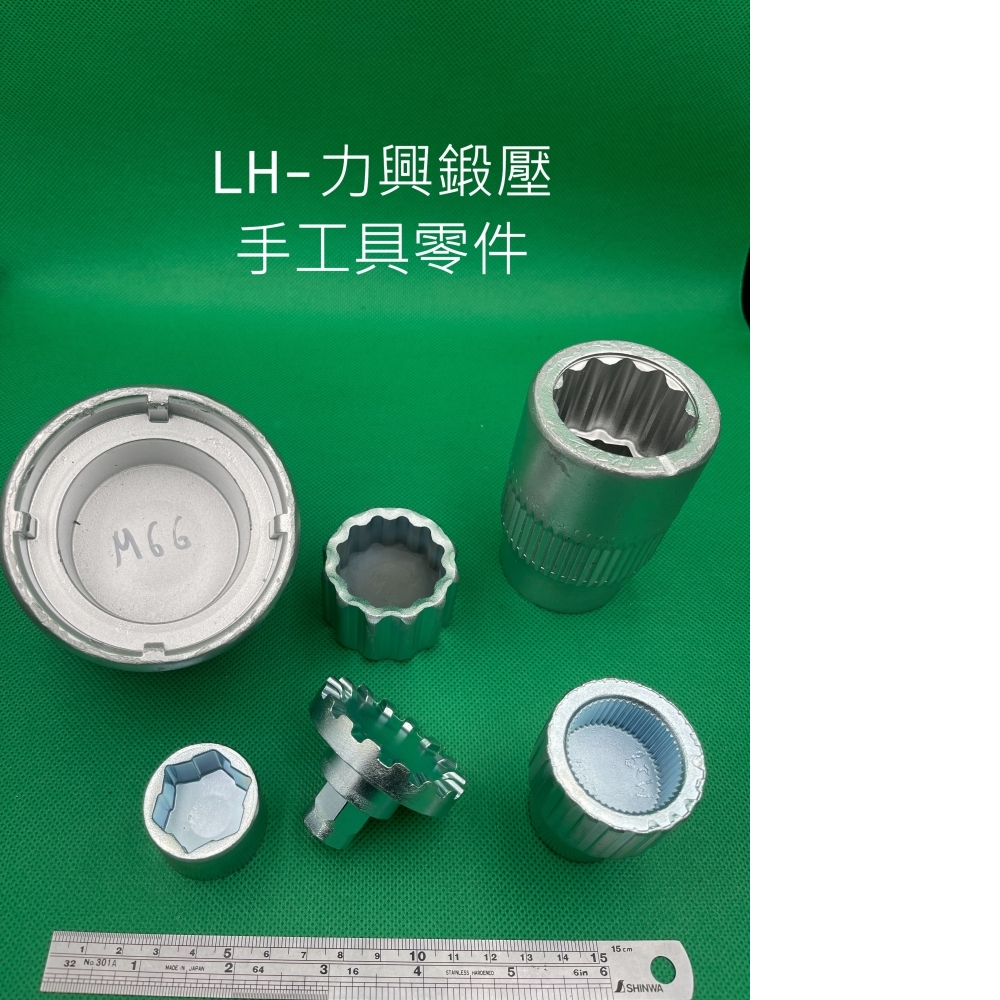

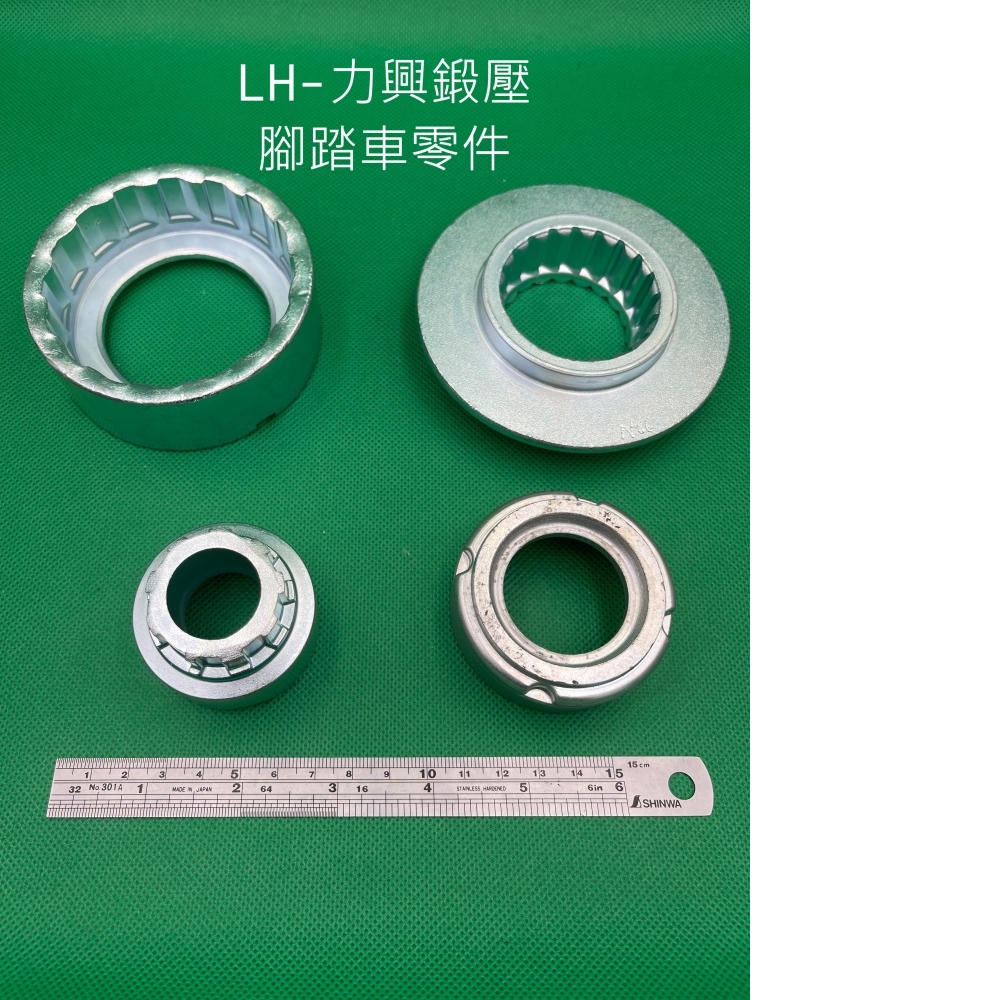

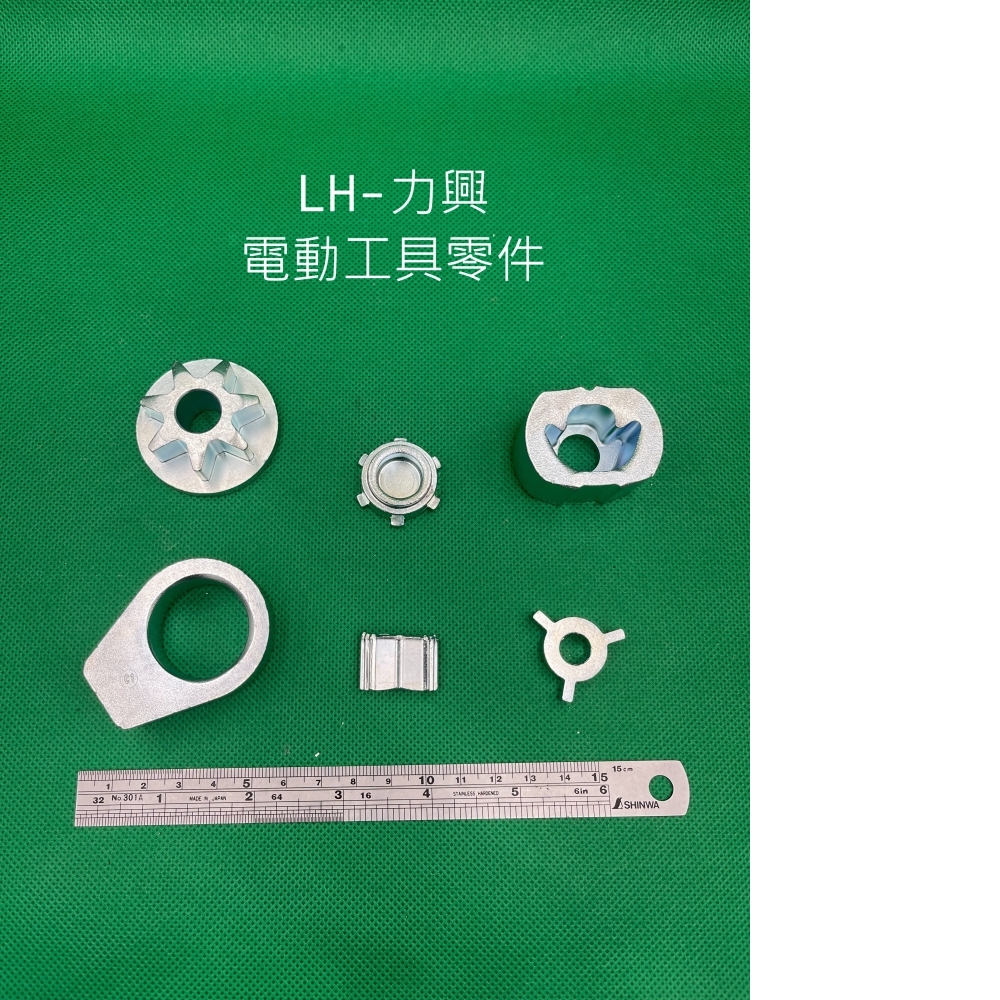

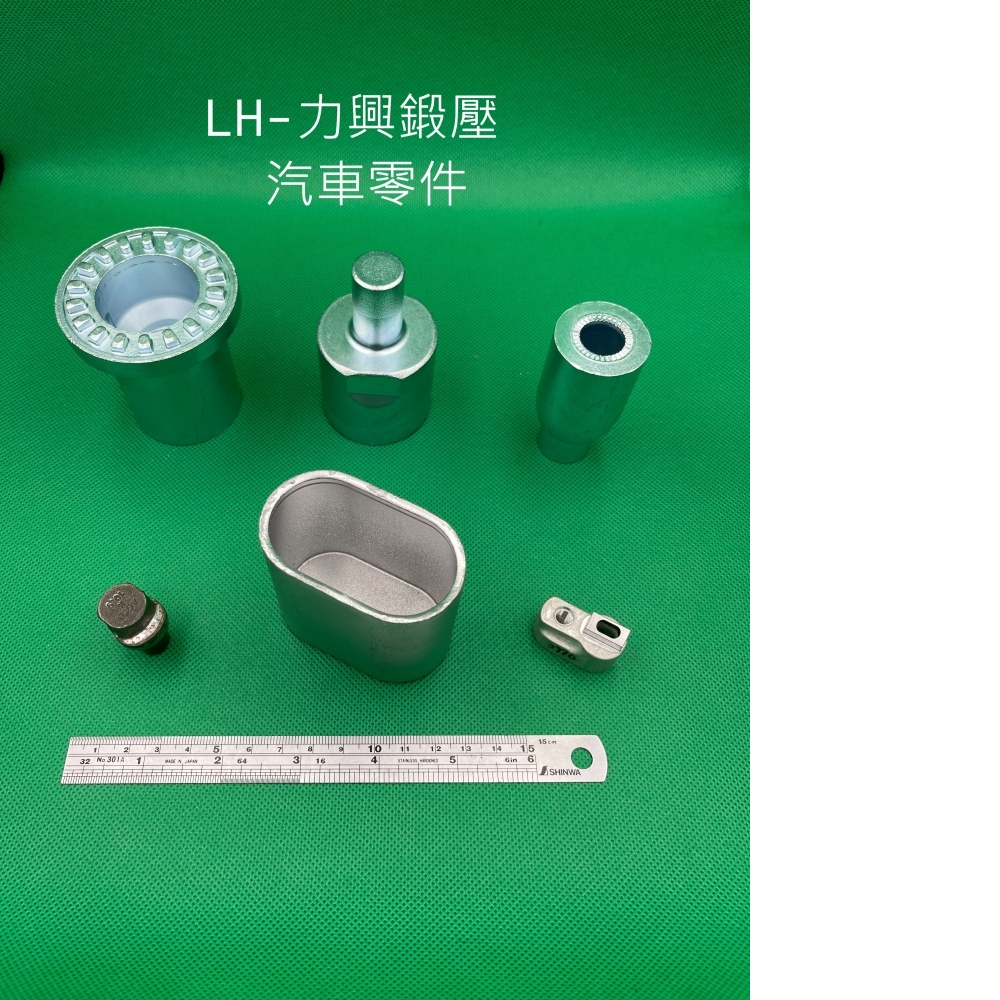

我們產品包括汽車零件、電動工具零件、氣動工具零件、機車零件、運動器材零件、機械五金零件、鋁合金零件、傳統腳踏車零件、電動腳踏車零件等。

公司沿革

-

2022

更新網站,改版成響應式網站。

-

2020

力興團隊通過科技部審核取得入駐二林中部科學園區之資格。

-

2019

力興團隊經過輔導,成功通過ISO9001:2015及IATF16949:2016國際證,認成為國際上合格汽車零件製造商。

-

2018

透過特殊模座達到3D鍛造之技術,成功量產溫間鍛造零件。

-

2014

成功開發電動工具槌擊塊零件。

-

2008

力興通過TS16949:2009 汽車工業品質認證, 成為國際上合格汽車零件製造商。

-

2006

遷廠至目前位於台中工業區廠址, 廠房大小是原先公司的四倍大。

-

2003

購買台中市工業區廠房土地並購入大量品管儀器, 冷鍛機及退火爐。

-

2000

力興通過ISO9001 品質系統認證, 成為合格金屬零件鍛造商。

-

1997

擴建台中市西屯區大河里197弄7號廠房,公司大小成為原先的二倍, 俾使公司更具規模,購入新冷鍛機及車床等設傋。

-

1994

大量投資自動化設備, 購入日本會田株式會社自動化沖床機器,並發展密閉式成型冷間鍛造,使鋼鐵更具附加價值。

-

1988

更新廠房,增加設備及電力,擴大營業,購得申琦公司冷鍛機10 部,大量生產汽車十字接頭零件及五金工具鍛造。

-

1984

公司創立於台中市西屯區大河里福上巷197弄11號,開始投入冷間鍛造行列。

產品介紹

-

鍛造設備 品名 單位 1200噸 沖床 1台 1000噸 沖床 1台 650噸 沖床 6台 400噸 沖床 13台 250噸 沖床 1台 160 噸 沖床 6台 160噸以下 沖床 6台

-

下料設備 品名 單位 斬料機台 3台 鋸料機台 3台 臥式盤元下料機台 2台 板材下料機台 2台 - - - - - -

-

表面處理設備及退火設備 品名 單位 噴砂機 2台 自動表面處理線 1條 10噸 球化退火爐 3台 2噸 鋁料專用退火爐 1台 2噸 退火爐 6台 - - - -